Now the price of lithium has risen sharply, and some investors have transferred to the lithium mining market. Among them, lepidolite is a kind of lithium resource, and it also has development value. At present, the common methods for extracting lithium from lepidolite are mainly lime roasting, sulfuric acid roasting, sulfate roasting, chlorination roasting and pressure cooking. Let's understand the characteristics and advantages and disadvantages of these mica lithium extraction process methods.

The limestone sintering method of mica lithium is to mix mica and limestone (or mica and limestone respectively), and then roasting at 940~1050℃ (so that lithium minerals can be converted into water-soluble compounds). After roasting, the lithium minerals are extracted by normal temperature water immersion (lithium-micite exists in the immersion solution in the form of hydroxide).

Advantages: The lithium extraction process is simple, low cost, easy to obtain raw materials, low cost, can be directly used for the production of lithium carbonate.

Disadvantages: Due to the high roasting temperature, this process leads to high energy consumption, large material flow rate, large slag volume, and low lithium recovery rate, which is easy to cause serious secondary pollution.

Mica lithium extraction process with sulfuric acid roasting The quantitative lepidolite and sulfate are roasted at 150-300℃, and the obtained product is then secondarily roasted at 800℃. During the roasting process, the lithium in lepidolite is converted into easily soluble lithium sulfate, and then leached under normal temperature water to obtain lithium resources.

Advantages: The process is highly versatile and can decompose various lithium-containing minerals. During the process, the aluminum in the lepidolite is almost not replaced, and the impurity content is small, the leaching rate is high, and the process flow is relatively simple.

Disadvantages: To ensure the leaching rate of lithium, a large amount of potassium sulfate needs to be consumed, resulting in a high concentration of potassium sulfate and sodium sulfate in the solution, and it is easy to form complexes of Li-Na-K or Li-K with low solubility with lithium sulfate. Salt. Products are also often polluted by potassium and have higher energy consumption. The amount of slag is large and difficult to utilize, and the cost is high. Expensive rubidium and cesium remain in the slag and cannot be extracted, and more fluorine and sulfide waste gas will volatilize during the high-temperature roasting process, causing serious environmental pollution.

The method of sulfate roasting mica is to use sulfuric acid to react with lithium mica, hydrogen ion to generate soluble lithium sulfate, and then soak in warm water, purify impurities and add carbonate to make it react again to get lithium carbonate products.

Advantages: no need for high temperature roasting reduces the energy consumption, and the amount of waste residue is small, and the lithium extraction efficiency is good.

Disadvantages: This method has high requirements for the fineness of lepmica, long leaching reaction time, and large potassium salt consumption.

Chlorination roasting lithium extraction is to mix lemicite and chloride (sodium chloride and calcium chloride, etc.) in a certain proportion and grind ore. After reaching a certain fineness, roasting under the condition of 900~950℃ to convert lithium minerals and other valuable metals into soluble chloride, and then leach to obtain lithium solution.

Advantages: Using this method can improve the conversion rate of lithium, high recovery rate, and short reaction time, less waste residue.

Disadvantages: In the process of roasting, due to the serious corrosion of chloride ion on the equipment, so the anti-corrosion requirements are relatively high, and there are big problems in environmental protection.

The pressure boiling method is to make the lithium cloud mother roasted and defluorinated, and then wet grinding in a certain proportion. After reaching the appropriate fineness, the reaction is under the pressure of> 200℃ and 0.2~2MPa, and the sodium ion can effectively replace the lithium ion. The replaced lithium ions are soaked in warm water. During the process, carbon dioxide should be injected into the water to convert lithium carbonate into soluble lithium carbonate. After solid-liquid separation, lithium bicarbonate solution is obtained, and lithium carbonate products are obtained after heating and decomposition.

Advantages: the process flow is simple, the material circulation is small, small equipment corrosion, low energy consumption, will not generate a large number of low-value by-products.

Disadvantages: this process needs to consume more carbon dioxide, and needs more expensive sodium carbonate, high requirements for equipment, strong corrosion resistance, and lithium recovery.

The above is the introduction of different mica lithium extraction process method and its advantages and disadvantages. Each process has its own characteristics, but in the actual concentrator, how to choose the process should be determined according to the nature of lithium micite ore. Therefore, Xinhai suggested to conduct the mineral processing test analysis first, and customize the process through the data, which has obtained an ideal recovery rate.

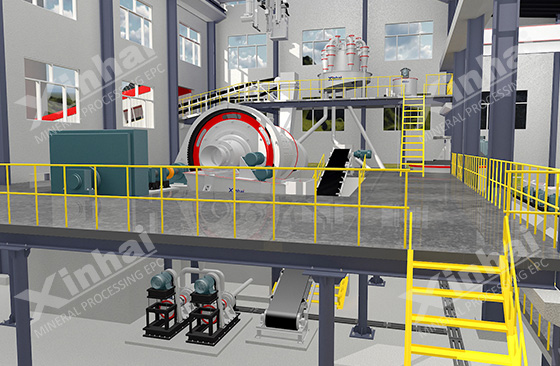

Xinhai Mining is an enterprise providing "the whole mining industry chain service"(EPC+M+O), which can provide users with beneficiation test, test analysis and design of reasonable beneficiation process and beneficiation plant construction scheme. In terms of equipment, Xinhai can provide complete sets of lithium ore mineral processing equipment, and the concentrator equipment installation and debugging services. The elected plant enters the operation stage, and Xinhai can also provide one-stop operation and management services.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.