Steel construction is a versatile and durable material used in various applications. It is strong, lightweight, and relatively easy to work with, making it a popular choice for many construction projects. Many mineral processing plant constructions have begun using steel structures, mainly for mineral processing platforms, operating platforms, desorption electrolysis systems, thickeners, and other equipment support.

So, what are the advantages of steel structures in mineral processing plant construction? Please read this article, which will introduce you in detail.

Steel structure mainly comprises steel beams, columns, trusses, and other steel profiles and plate components. Welds, bolts, or rivets usually connect the elements or parts. Common steel profiles include I-beams, hollow structural sections (HSS), channels, angles, and steel plates. As a new structural form, steel structure has the following outstanding advantages over a traditional concrete structure:

Fast and efficient construction: Prefabrication and easy assembly of steel structures can reduce construction difficulty and shorten construction time.

Excellent strength-to-weight ratio: Steel members have a small, compact cross-section and weigh about 60% less than concrete. Yet they are extremely strong, much stronger than common building materials such as concrete and wood.

Low overall cost: In Southeast Asia or Africa, the cost of concrete is very high, mainly because some materials need to be imported, adding to the overall construction cost. A typical steel framing system is 5% to 7% less expensive than a reinforced concrete one. It also reduces indirect costs such as equipment rental and personnel management due to the shorter construction period.

Flexible Spatial Layout: Steel's flexibility allows it to be easily molded into shapes, sizes, and thicknesses that fit the building's needs. A steel structure can realize a 20- 30 meter wide span, which is easy to remodel.

Material recyclability: The recycling rate of steel structure components is over 95%, and the dismantled steel can be re-smelted for other projects.

Less construction dust and noise, less pollution: Steel structure construction dust emissions are 70% less than those of concrete structures, and noise pollution is 50% less. The recycling of steel can offset the carbon emissions of the production process, which is in line with the concept of a green mine.

1. Professional Design Institute for Support

Xinhai China has its steel structure section of the design institute, which can design and calculate, produce design drawings, and model and process drawings according to the process conditions.

2. BIM digital information model

✦Xinhai Steel Structure adopts BIM technology for 3D modeling. During the project's life cycle, the digital information model is used to discover and avoid risks in advance, realize lean management, improve efficiency, and save time and cost.

✦3D design is more intuitive: traditional two-dimensional design requires certain spatial imagination of the design, processing, and installation personnel, while 3D design, through rendering, has realistic three-dimensional effects and can roam anywhere to optimize the design. The steel structure components processed by the factory after 3D design can meet various usage, logistics, and transportation requirements. Purchasing, processing, and installation can be directly guided, so that design and construction are closely linked.

✦Steel structure design without obstruction: traditional 2D design relies on manual checking, which can't avoid the phenomenon of "touching, leaking and missing" of the project, resulting in project rework, while 3D steel structure design can prevent the collision problem in the design, and put an end to the unnecessary rework and waste.

3. Model virtual simulation roaming, early warning management

Through BIM visualization and collaborative design, clash checking and optimization can be carried out to eliminate design errors.

4. Standard modularized steel structure

There are various models of desorption electrolysis steel platforms, thickener steel legs, flotation machine operating platforms, and other standard modularized steel structures.

For example, the standard platform of flotation machines, under the premise of practicality, safety, and economy, has innovated the overall modularization, which can be adapted to the configuration of different lengths of different numbers of flotation machines.

The process can choose several platform modules according to the number of flotation machines, and it is very convenient to use several platform modules together by bolting on-site.

5. Full bolt combined steel structure

The model adopts a full bolt connection, which reduces welding workload, avoids special operations, ensures project quality, and saves construction costs. The bolt connection is convenient to install and can be dismantled repeatedly.

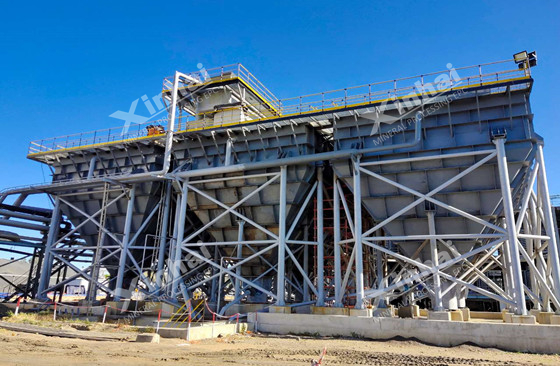

South Africa 3000tpd chromite flotation beneficiation plant

Mongolia gold ore 1.2 million tpa complete plant

Mozambique 10,000tpd heavy sand ore wet separation production line

Guinea 15000tpd gravity separation + carbon slurry plant west concentration plant

In summary, combined steel structures provide benefits such as quick installation, flexibility, stability, and easy expansion in beneficiation plants. Xinhai employs BIM technology and a fully bolted modular steel structure, ensuring advanced and intelligent design. Contact us for customized beneficiation plant solutions and support!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.