At the end of 2020, the customer of the 2000TPD iron concentrate desulfurization plant project contacted Xinhai Mining and stated that the iron concentrate produced by its project had a high sulfur content and was difficult to meet subsequent use needs. It hoped to obtain more qualified iron concentrate products through a new process plan. After a preliminary understanding of the project information, Xinhai Mining provided the customer with a rough technical plan and quotation. The customer was very satisfied with this and signed a follow-up project contract with Xinhai Mining. In 2022, the project undertaken by Xinhai Mining will be successfully constructed.

Based on the test samples sent by the customer, Xinhai Mining prepared the test samples and obtained three parts of the test sample, the screening sample and the laboratory sample, and simulated the original process flow of the project site to prepare the iron concentrate to maintain floating stable and uniform iron grade and sulfur grade of raw ore.

After comparative analysis of multiple sets of tests, Xinhai Mining proposed a suitable process plan and chemical system for the project. It adopted a flotation operation of one coarse and two sweeps, and used xanthate and black powder as mixed collectors to flotate sulfur minerals. Using copper sulfate and oxalic acid as combined activators can not only effectively reduce the cost of chemicals, but also ensure the sulfur removal effect of the concentrate.

After determining the process flow, Xinhai Mine Design Institute made a comprehensive plan for the project, carried out customized construction drawing design, and reasonably laid out various equipment and pipeline lines.

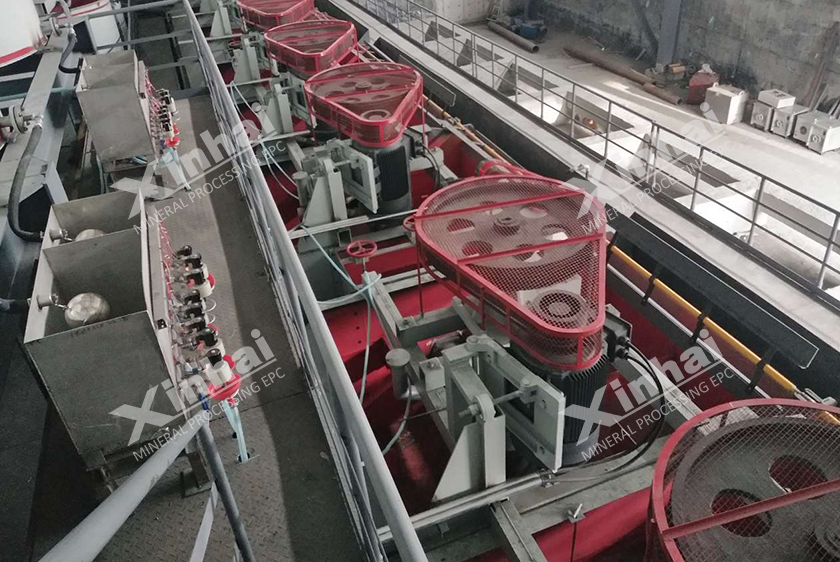

In order to make the equipment meet the needs of the process flow, Xinhai Mining made customized adjustments and transformations to the selected equipment, and customized the main and auxiliary equipment of the flotation production line of the project to reduce equipment energy consumption, increase equipment productivity, and extend the equipment stable operating time. Xinhai Mining uses a numbering and manual management system to ensure that the equipment and spare parts are complete, and is classified and packaged according to on-site installation needs and transportation needs to ensure equipment safety.

After equipment of the project arrived, Xinhai Mining appointed an experienced installation and commissioning team to assist in the installation and commissioning of the project. The installation of all equipment was completed within half a month, and after passing process indicator debugging, the project was officially put into operation.

Since it was put into operation, the 2000TPD iron concentrate desulfurization plant project has been operating stably and the equipment quality is reliable. After completing the debugging of process indicators, the sulfur grade in the iron concentrate was reduced to less than 0.15%, and even reached 0.065%, which greatly exceeded the expected indicators of the project. The customer was very satisfied with this.

Please leave your message here! We will send detail technical info and quotation to you!

© 2020 Shandong Xinhai Mining Technology & Equipment Inc.