If you want to know more information, like quotation, products, solutions, etc., please contact us online.

The development of the steel industry has a direct impact on the development and utilization of iron ore resources. As the steel industry has higher and higher requirements for iron ore quality, it is necessary to improve the development of poor ore resources while utilizing high-quality ore resources. In order to meet the needs of the steel market, it is necessary to continuously update and improve the existing iron ore resource beneficiation technology and equipment. Iron ore is very complex in terms of both process type and geological composition, and there is a relatively complex symbiotic relationship between iron ores. Therefore, it is necessary to ensure the rationality of iron ore processing technology to improve the quality of concentrate and improve the economic benefits of beneficiation. Magnetite is one of the main types of iron ore resources, and it accounts for a high proportion of iron ore resources. Choosing a suitable magnetite beneficiation process is also one of the effective ways to make full use of iron ore resources. The following article will introduce you to the beneficiation equipment, process and magnetite beneficiation process of iron ore, to help you better understand iron ore processing technology.

Use the table of contents below to navigate through the guide:

With the continuous development and utilization of high-quality iron ore resources, the utilization of lean ore has gradually attracted attention. Due to the large proportion of lean iron ore resources, large-scale beneficiation of iron ore is required. From the perspective of beneficiation technology, iron ore can be divided into multi-metal composite iron ore, weak magnetic iron ore, mixed iron ore and magnetite. Since composite iron ore has a certain amount of metal and non-metallic minerals, it can be used as an independent ore type with obvious characteristics.

When crushing ore, beneficiation plants often use three processes of coarse crushing, medium crushing and fine crushing to process iron ore. Gyratory crusher is used for coarse crushing, standard cone crusher is used for medium crushing, and short-head cone crusher is used for fine crushing. After completing medium and fine crushing, the product with qualified particle size is processed in the grinding tank.

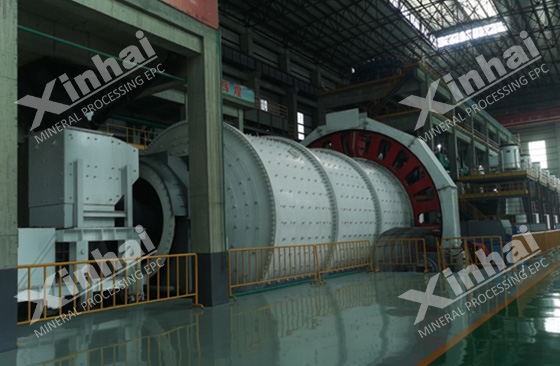

The iron ore grinding process can be divided into two-end grinding process or one-stage grinding process. Small and medium-sized beneficiation plants prefer to choose one-stage grinding process. The grinding equipment used in actual production is relatively small. After grinding, a spiral classifier is usually used to classify the ground ore. A hydrocyclone can also be used to improve the grading efficiency of the ore.

The magnetite beneficiation process can be divided into three categories: pre-selection process, single magnetic separation process and gravity magnetic flotation combined process.

(1) Magnetite pre-selection process

The crushed magnetite product needs to be pre-selected before entering the grinding and selection workshop, mainly to discard the low-grade conjoined bodies and gangue minerals, and provide higher quality raw materials for subsequent sorting. Pre-selection can be divided into wet pre-selection and dry pre-selection. Wet pre-selection is to use a wet magnetic separator to complete the processing of the ore, while dry pre-selection mainly refers to the use of magnetic pulleys to achieve the processing of the ore.

(2) Single magnetic separation process

The single magnetic separation process can be used to process magnetite and vanadium-titanium magnetite, and can achieve effective recovery of magnetic iron. After the magnetite is crushed and ground to maintain a reasonable particle size, it enters the magnetic separation process. Generally, three-stage rough magnetic separation and one-stage fine separation process are selected. The final product is the magnetite concentrate. Wet magnetic separators are often used for rough magnetic separation. They have two structural types: countercurrent and semi-countercurrent. Magnetic columns are often used in the fine separation process.

(3) Combined gravity and magnetic flotation process.

When hematite coexists in the ore, the combined gravity and magnetic flotation process can be used. Hematite is generally distributed in the shallow part of the ore deposit, and magnetite is in the deep part of the ore deposit. If you want to recycle these two iron resources, use the combined gravity and magnetic process to recover the magnetite, and then recover the hematite through flotation operations.

The above content is a brief description of the beneficiation process and equipment for iron ore and magnetite. According to the type of iron ore resources, reasonable beneficiation process and equipment are selected to improve the beneficiation efficiency and obtain qualified and high-quality iron concentrate. Xinhai Mining can tailor-make beneficiation plans for different types of iron ores such as hematite and magnetite, and provide a full set of iron ore processing equipment. Welcome to consult Xinhai Mining for more information about EPCM+O services.

Please leave your message here! We will send detail technical info and quotation to you!

© 2020 Shandong Xinhai Mining Technology & Equipment Inc.