In mining production, ball mill is one of the key equipment. Its operation, maintenance and handling of common problems directly affect production efficiency and cost. This article will analyze the key points of ball mill maintenance and operation in detail, and explore common problems and their solutions.

The factors that are relatively fixed and do not need to be adjusted frequently in ball mill operation include the hardness of the original ore, the size of the crushed particle size, the mesh of the grid screen, the model of the ball mill, the quality of the steel ball, the amount of steel ball added, the ratio of the size of the steel ball, the speed of the ball mill, the speed of the classifier, etc. These factors have been determined in the early stage of design and process formulation. Although many ore dressing plants may have problems in design, equipment installation or equipment quality, understanding these fixed factors will help maintain the stability of ball mill operation.

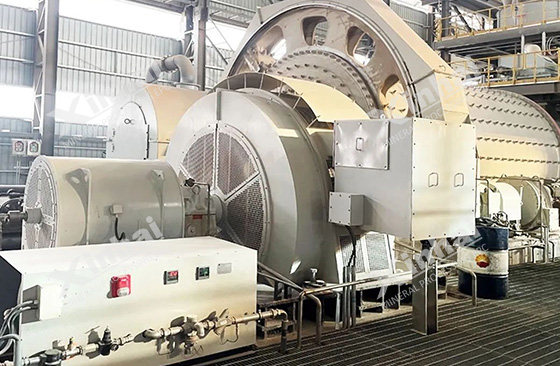

Different ball mill machine can meet different process technology requirements. When designing, the ball mill model must be reasonably selected according to production needs to ensure that it can adapt to specific process requirements. Choosing the right model is the basis for optimizing the production process and improving efficiency.

1. Wet Grid Ball Mill

Structural Features:

Uses large double-row self-aligning roller bearings instead of sliding bearings, greatly reducing friction, making start-up easier and saving 20–30% energy.

Equipped with a grooved ring plate liner to increase contact between steel balls and ore, enhancing grinding efficiency and lifting capacity while lowering energy consumption.

Large discharge opening ensures high throughput.

Oil mist lubrication system guarantees reliable lubrication of gears.

Application:

Best for grinding coarse materials (product size 0.2–0.3 mm). Commonly used in first-stage grinding to prevent overgrinding and improve efficiency.

2. Wet Overflow Ball Mill

Structural Features:

Adopts large double-row self-aligning roller bearings, reducing friction and saving 20–30% energy.

Grooved ring plate liner improves grinding performance and ore lifting, reducing power consumption.

Oil mist lubrication ensures reliable operation of large and small gears.

Application:

Suitable for fine grinding with product size below 0.2 mm. Often used in second-stage grinding or regrinding of intermediate products.

3. Dry Ball Mill

Structural Features:

Operates without adding water during processing.

Can be used for open-circuit or closed-circuit grinding with a powder classifier.

Features strong adaptability, continuous operation, and adjustable product fineness.

Feed moisture must be low to avoid material bonding and discharge issues.

Application:

Ideal for dry materials such as coal and cement.

During the installation of the ball mill machine, problems such as eccentricity and meshing deviation of large and small gears may occur, which will affect the normal operation of the equipment. The gears of the reducer may have defects such as sand holes, which will increase gear wear and affect the working efficiency of the ball mill. The equipment must be installed in strict accordance with the standards to reduce the occurrence of these problems.

Employees responsible for ball milling need to master the important parameters for daily adjustment, which directly reflects the operating level and grinding utilization rate, such as the water supply size of the ball mill, the flushing size at the discharge port of the ball mill, and the feed size. Mastering the adjustment skills of these parameters can effectively improve the working efficiency and product quality of the ball mill.

| Parameter | Adjustment | Notes & Precautions |

|---|---|---|

| Feed Rate | Keep consistent with mill load, motor current, and discharge density. | Excessive feed causes overloading (“belly grinding”); too little feed lowers grinding efficiency. |

| Feed Size | Control within the design range (e.g., ≤25 mm). | Oversized feed increases liner and media wear, and may cause poor grinding. |

| Pulp Density (Slurry Concentration) | Usually controlled between 65% and 80% for wet grinding. | High density reduces pulp flow; low density weakens grinding impact. |

| Ball Load (Media Filling Rate) | Typically 35%–40% of mill volume. | Replenish worn media regularly to maintain grinding efficiency. |

| Discharge Density & Product Size | Check and sample regularly. | Coarse discharge indicates reduced grinding efficiency — adjust feed or add balls. |

| Water Addition | Adjust to maintain suitable slurry flow and grinding condition. | Too much water lowers grinding efficiency; too little may cause mill clogging. |

The precursors of ball mill bulging mainly include the following aspects: observe whether the ball mill feed port spits out materials, listen to whether the sound of the ball mill becomes smaller and muffled, and check the current value changes of the ball mill current control cabinet.

Ball mill bulging is usually caused by a large amount of ore, which leads to coarser ore particle size, resulting in less work done by the ball mill, lower efficiency of converting electrical energy into kinetic energy, and smaller current value. Understanding this phenomenon and its principle can help operators find problems in time and make adjustments.

Grinding fineness is one of the key factors in mineral processing, and has a direct impact on the concentrate grade and product recovery rate. To effectively improve the grinding fineness, it is necessary to pay attention to the following key factors:

1. Hardness of the raw ore: Different ore hardness will affect the grinding effect. Ores with higher hardness require longer time and higher grinding intensity to achieve the ideal fineness.

2. Crushing particle size: The initial crushing particle size of the ore has a direct impact on the grinding fineness. Ores with larger particle sizes take longer to grind, and proper adjustment of the crushing particle size can improve the grinding efficiency.

3. Steel ball size and quantity: The size and quantity of steel balls directly affect the grinding effect of the ball mill. Properly increasing the number of steel balls or adjusting their size ratio can improve the grinding fineness.

4. Ball mill speed: The speed of the ball mill determines the collision frequency and intensity of the steel balls and the ore. Adjusting the appropriate speed can improve the grinding effect, but excessive wear caused by excessive speed should be avoided.

By rationally adjusting these factors, the grinding fineness of the ball mill can be optimized, thereby improving the mineral processing efficiency and product quality.

The hardness of ore is fixed and cannot be adjusted, but the ore size can be made as uniform as possible by reasonable ore mixing in production. The ratio of lump ore and powder ore should be reasonable and stable to improve the working efficiency of the ball mill. The belt at the feeding point of the ball mill will leak ore due to wear, and most of the leaked ore is powder ore. The leaked ore should be added to the ball mill in time to avoid uneven feeding, which will cause unstable production.

Through a detailed analysis of ball mill operation, maintenance and common problems, it can help operators better understand and cope with the challenges of ball mills in actual production. Mastering these key points will help optimize the production process and improve production efficiency and economic benefits.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.