The grinding process can be divided into one-stage grinding and two-stage grinding. In actual production, the concentrator will adjust the grinding process according to actual production requirements, so different types of grinding processes will be formed. Below we will introduce to you the types of one-stage grinding and two-stage grinding processes and their characteristics.

The open circuit grinding process is prone to over-crushing. Usually, grinding equipment and classification equipment need to form a closed loop. There are three commonly used processes: a one-stage grinding process with inspection and grading; a one-stage grinding process with pre- and inspection grading; and a one-stage grinding process with controlled grading.

If you want to use a one-stage grinding process to obtain products with finer particle size, or if you must use a one-stage grinding process due to production budget, it is recommended to choose a one-stage grinding process with controlled classification. Controlled classification can produce finer ore particles. This process is suitable for small mineral processing plants.

Using a two-stage grinding process, finer grinding products can be obtained. At the same time, the two-stage grinding process can also be applied to stage separation. The two-stage grinding process can be divided into: the first stage is open circuit, the first stage is fully closed circuit, and the first stage is partially closed circuit according to the different connection methods with the classification equipment. Because the first stage of grinding will produce a large amount of products with qualified particle size, so the second stage Pre-grading before segmentation is necessary.

There is no overflow and re-classification in the two-stage grinding process with the first stage open, so the required grading area is smaller. The grinding discharge of the first stage is directly passed to the second stage, there is no distribution problem in the grinding section, the process adjustment is relatively simple, and the grinding product with finer particle size can be obtained. Generally, a rod mill is used to grind the ore in the first stage, which can improve its grinding efficiency.

If the first section adopts an open circuit, the volume of the grinding equipment in the second section will far exceed that of the first section, resulting in a heavier load on the equipment. Since the ore discharged by the open circuit has a coarse particle size and high concentration, special mechanical transportation devices are required, and the configuration is relatively complex, causing inconvenience to management. This process can be adopted in large-scale mineral processing plants.

The first fully closed-circuit two-stage grinding process can process ores with high hardness and fine particle size. This process can also be used in medium and large concentrators with grinding requirements below 0.15mm.

Using the first stage of fully closed-circuit grinding process can achieve fine grinding and obtain finer grinding products. The equipment configuration is relatively simple, and the two stages of grinding equipment can be installed at the same level. However, the adjustment between the two stages of grinding in this process is more difficult. The obtained mineral particle size is basically less than 0.2mm. The processed ore needs to flow through the overflow weir twice, the total classification area is large, and the equipment investment is high.

The first partial closed-circuit process does not have the problem of load distribution in each grinding section, and the process adjustment is relatively simple. Each stage of the grinding process is discharged and circulated, and at the same time, a final product that is coarser than the product of the two-stage closed-circuit grinding process can be obtained, which can avoid the accumulation of precious metals in the grinding cycle.

The disadvantages of the partially closed-circuit process are: transporting the returned sand from the first stage to the second stage requires the use of a chute with a steep slope or the use of transportation machinery; the inspection and classification of the grinding in the second stage requires the processing of ore that produces a small amount of secondary sludge. It will cause difficulties in the operation of the grader.

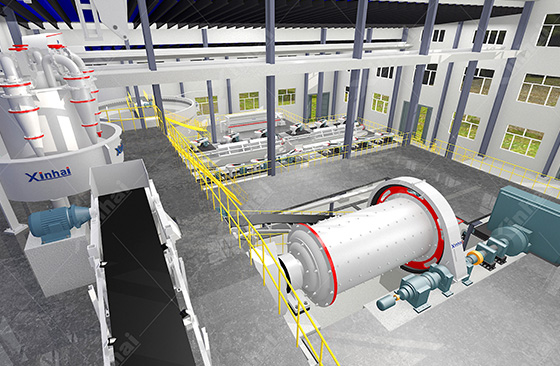

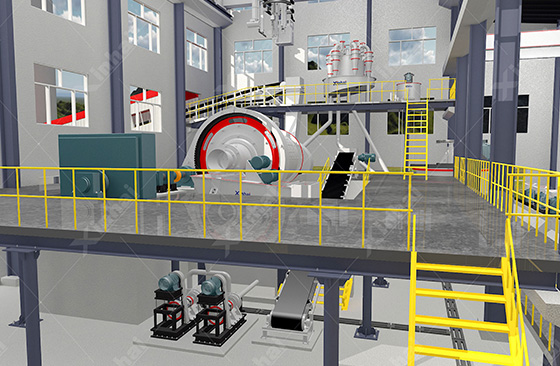

The above contents are the types and characteristics of one-stage grinding and two-stage grinding processes. According to the production requirements of the mineral processing plant and the characteristics of the ore itself, selecting an appropriate grinding process can improve resource utilization and concentrate recovery. Xinhai Mining can provide you with customized grinding processes and equipment, and can also provide complete mineral processing production line design and equipment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.