Nowadays, easy-to-separation gold ore resources are decreasing. The hard-to-separation gold ores become the object of development and research. The below takes a kind of hard-to-separation gold ore as an example to introduce the gold beneficiation process and equipment which are needed in ore beneficiation plant.

The gold ore exists in the form of natural gold, mainly wrapped gold, followed by intergranular gold and fissure gold. Other metal mines are mainly pyrite, pyrite, pyrite and oxite, followed by magnetite, pyrite, limonite, hematite, chalcopyrite, zinc blinite, galena, rutile, etc. There are also a small or trace of copper blue, tetrazoite, magnetite, ilmenite, rzine, white lead, sulfur antimony lead and so on. Gangue minerals are mainly quartz, with a small amount of feldspar, calcite, dolomite, chlorite, sericite, etc. Trace minerals are kaolin, yellow potash iron alum, graphite, apatite, zircon and so on.

According to the properties of the gold ore, the designed gold beneficiation process is crushing&grinding-coarse selection-sweeping -regrinding-fine selection.

This stage applies three-stage one-closed-circuit crushing process. After crushing, the mineral particle size should meet the requirement of-3mm. Rotary crusher is used for coarse crushing, jaw crusher is used for medium crushing, single cylinder cone crusher is used for fine crushing, DZS linear vibrating screen is used for fine screening, and its screening efficiency is high.

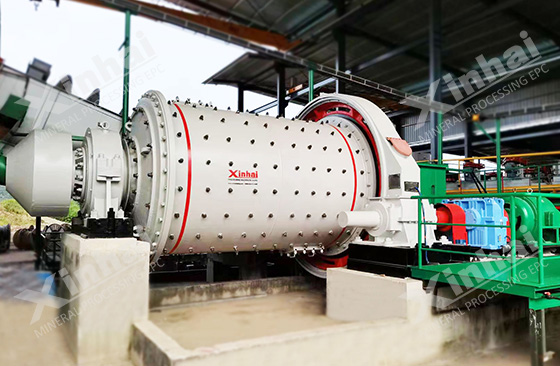

The grinding process adopts two closed circuit grinding processes, so that the grain size of the gold mine reaches-0.074mm for 85%. One section of the mill operation uses a grid type ball mill. The second section grinding machine uses the overflow type ball mill, and the grinding&classifying system is formed in the spiral classifier machine to ensure that the grinding fineness meets the requirements.

The rough selection process of this gold mine is a single rough selection process. After grinding, the qualified products are sent into the agitation tank and add the dressing agent to stir fully, and they are pumped into the SF flotation machine for crude selection. The flotation agent mainly uses Na2CO3 as pH regulator to make pH=8, T101 as dispersant, CuSO4 as activator, D3 as collector, and oil 2 as foaming agent.

In the sweeping selection stage of the gold mine, one-stage sweep process is adopted, in which the tailings are swept after coarse selection. By adding quantitative T101, CuSO4, D3 and 2 oil, the JJF flotation machine completes the sweep operation, and the final concentrate products are sent to the selection stage.

The regrinding process is mainly to disentangle the gold mineral and obtain higher grade final gold concentrate. It is to regrind the coarse concentrate obtained after coarse selection, and the process adopts a closed-circuit grinding process. Use overflow ball mill to grind coarse concentrate to-0.043mm. In addition, the ball mill will provide the quantitative T 101 dispersant to ensure the effective separation of the gold product and the yellow iron impurities, and the final product will be sent to the selection stage.

In this stage, two sections of selection process are adopted to send the qualified minerals into the agitation tank after regrinding and sweeping. After adding appropriate agents, the pump pumps them into the KYF flotation machine for one selection operation, and then the XCF flotation machine inhaled it to complete the second selection operation and obtain qualified gold concentrate.

The equipment required for the gold ore concentrator is mainly crushing and screening equipment, grinding and classifying equipment, flotation equipment and some auxiliary equipment.

Gyratory Crusher, Jaw Crusher, Single Cylinder Cone Crusher and DZS Linear Vibrating Screen. Gyratory crushing is used for coarse crushing, and the ore particle size ranges from 75 to 320mm. The jaw crusher is used for intermediate crushing, and the ore particle size ranges from 22 to 75mm. The cone crusher is used for fine crushing, and the ore particle size is ≤3mm. The linear vibrating screen configures the size of the screen according to the required particle size of each crushing stage to ensure that the screening particle size meets the standard.

Grid type ball mill, overflow type ball mill and spiral classifier. The grid type ball mill is equipped with a grid plate at the ore discharge place, which can perform forced ore discharge, and the output particle size is relatively coarse, so it is placed in the coarse grinding stage to complete the grinding operation. The ore discharge of the overflow ball mill is to rely on continuous feeding to squeeze and push it, and gradually send it to the ore discharge place. This kind of ball mill takes a long time to grind ore, and the grinding particle size is finer, so it is placed in the re-grinding stage to complete the fine grinding operation. At this stage, a spiral classifier will be set up to classify the grinding products. Qualified materials are sent to the selection section, while unqualified materials are returned to the regrinding stage to continue grinding.

The equipment used in flotation is mainly SF type, JJF type, KYF type and XCF type. According to the characteristics of the equipment, the rough selection, sweeping and selection are carried out to complete the operation.

During the period, there will be chemical agitation tanks at each stage to do auxiliary work to fully mix the ore pulp and chemical after grinding, which is convenient for flotation. In addition, in the configuration of the flotation machine, a slurry pump will be installed to transport the slurry to ensure the normal input and output of each flotation link.

The above is the introduction of the properties of the hard-to-separation gold ore, the beneficiation process plan and the required equipment. Through test analysis, the custom-made gold ore beneficiation process finally enables the refractory gold ore to obtain gold content of 41.76g/t and silver content of 38.59g/t, and the recovery rates of gold and silver are 89.21% and 78.10% respectively, achieving efficient recovery of refractory gold.

Xinhai Mining has very rich experience in gold ore beneficiation. Not only can we conduct beneficiation tests based on gold ore, design gold beneficiation process plans, and design gold ore beneficiation plant construction plans, but also provide complete sets of gold ore beneficiation plant equipment. If you need it, please consult.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.