Fluorite is an important non-metallic mineral resource that is widely used in metallurgy, chemical industry and other industrial fields. As one of the important raw materials for the production of building materials, it can be used in the production of glass, rubber, ceramics and other building materials. Therefore, the market has great interest in fluorite. The demand for stone shows a steady growth trend. In order to meet market demand, improving the utilization and recovery rate of ore resources is an important solution. According to the different gangue minerals in the ore, there are four types of fluorite ore: quartz type, carbonate type, barite type and sulfide ore type. Judging from the fluorspar deposits that have been developed, silicate fluorspar ores are more developed, but from the actual production point of view, carbonate fluorspar ores are better separated and have high beneficiation indicators. Because part of the fine grains in the silicate fluorite ore intersects with silica to form fine-grained contiguous bodies, it is difficult to desilicate and the mineral processing index is lower than that of the carbonate fluorspar ore. Different types of fluorspar ore will choose different types of mineral beneficiation process technology. The following will introduce you to the different separation technologies of fluorspar ore and the processing methods of the ore.

There are three main fluorspar beneficiation process methods used in actual concentrators: hand separation, gravity separation and flotation.

1. Hand selection method: It is mainly used for fluorite ore where the boundaries between fluorite ore and gangue minerals are clear and easy to distinguish with the naked eye. It is often used as an auxiliary means for other mineral processing methods.

2. Gravity separation method: The gravity separation of fluorite ore is mainly reflected in the heavy media pre-selection process. After heavy media pre-selection, most of the quartz can be thrown out, thereby reducing the impact on subsequent grinding operations.

3. Flotation method: As the raw fluorite ore gradually becomes depleted, the fluorite ore and gangue minerals are interwoven with each other, and the monomer dissociation can be achieved through fine grinding. For the separation of finely ground fluorite ore particles, flotation method is mainly used, so flotation method is the main separation method for sorting fluorite ore and gangue minerals.

According to the above, it can be seen that there are many kinds of fluorspar mines in nature, and different fluorspar mines use different beneficiation process technologies.

1. Quartz type and sulfide type fluorspar ore: For these two types of fluorspar ore, the flotation process and chemical system are relatively simple. The collector generally chooses oleic acid or oxidized paraffin soap, the slurry pH adjuster generally chooses sodium carbonate, and the inhibitor chooses water glass. After multiple selections of fluorite ore, high-grade fluorspar concentrate can be obtained. To sort sulfide-type fluorite ore, you can first use xanthate or black powder to float out the sulfide, and then use fatty acid collectors to float out the fluorite ore concentrate.

2. Carbonate-type fluorite ore: Both the fluorite and the gangue mineral calcite in this type of fluorite ore contain calcium ions, and due to their similar solubility, it is easy for minerals to transform into each other when they coexist in the solution. , which makes it difficult to separate fluorite ore and calcite. For this problem, selecting appropriate inhibitors is the key to separating fluorite and calcite. The types of inhibitors used in flotation include water glass, sodium hexametaphosphate and humic acid. When the pH value of the slurry is in the range of 8-9.5, oleic acid can effectively capture calcite and fluorite, and then use inhibitors to adjust the difference in floatability of the two minerals, thereby sorting fluorite and calcite.

3. Barite-type fluorite ore: The cations of fluorite are both alkali metal ions, and the separation from barite is a difficulty in its flotation process. There are two methods for separating fluorite and barite: first suppressing barite and then flotating fluorite, or first suppressing fluorite and then flotating barite. Studies have found that trivalent cations such as aluminum ions and iron ions have an inhibitory effect on barite, but have an activating effect on fluorite, while divalent barium salts and lead salts can inhibit fluorite from activating barite. The key to the separation of fluorite and barite lies in the role of selective inhibitors. When the barite ore content in fluorite ore is high, gravity separation methods such as spiral chute + shaking table can be used to separate fluorite and barite.

Middle ore processing is an important part of the mineral processing process. For fluorspar beneficiation, the quality of the concentrate is very demanding, so the number of times of fluorspar beneficiation is high, up to six times. But the treatment of middlings during the beneficiation process is a key issue. There are generally three treatment options for fluorite concentrate: sequential return, centralized return and separate treatment. When processing uniformly distributed ores, or when the quality of the concentrate is not high, the sequential return scheme can be used to improve the recovery rate of the concentrate. If the ore being processed is coarse-grained and unevenly distributed or the quality of the concentrate is required to be high, a centralized return scheme can be used to ensure the quality of the concentrate.

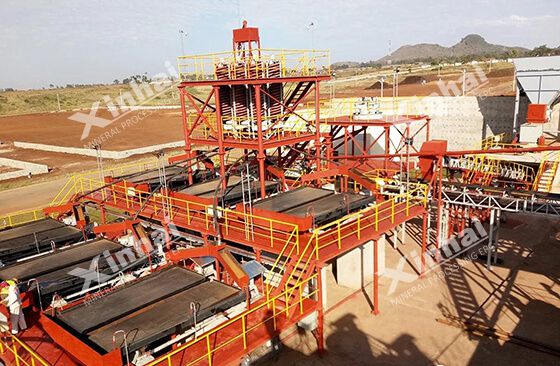

The above is a brief introduction to the fluorite ore beneficiation process method and the medium ore processing method. In the actual production of the dressing plant, the mineral processing plan needs to be adjusted appropriately according to the production situation to improve the processing efficiency of the production line and the recovery rate of the concentrate. Xinhai Mining can customize a fluorite mineral processing plan for you based on the mineral processing test results. We also provide efficient mineral processing equipment to help you achieve efficient separation of fluorspar ore.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.