Graphite flakes have good floatability, and their quality is closely related to the size of the flakes. Therefore, attention should be paid to protecting large flakes from damage during the sorting process, which also increases the difficulty of mineral processing. The traditional beneficiation method of flake graphite is to regrind the coarse concentrate in multiple stages and then select it to recover useful minerals as soon as possible. However, this complex grinding-flotation process destroys most of the large graphite flakes that have been dissociated from the monomer. Therefore, the multi-stage grinding and multi-stage separation method cannot protect the graphite flakes. Understand the factors that cause scale damage and affect the quality of concentrate, and adjust the process according to actual conditions to improve mineral processing efficiency. These factors include grinding media, grinding fineness, number of regrinding stages, flotation equipment, etc. Let’s take a look at them together.

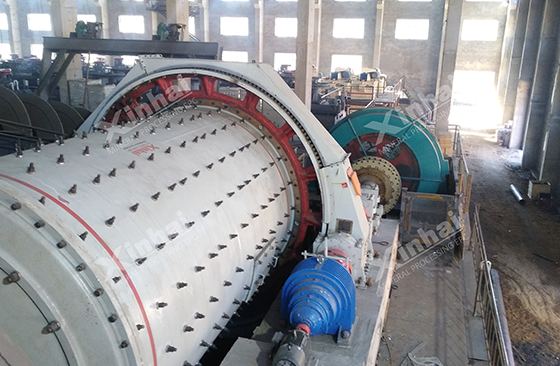

In the process of graphite beneficiation, the quality of the regrinding effect directly affects the quality of the concentrate and the output rate of large scales. Therefore, it is crucial to select reasonable regrinding equipment. Different grinding media have different effects on large scales. Due to the different contact methods between different grinding media and minerals, their grinding efficiency is different and they have different degrees of protection for large graphite scales. Ball mills cannot effectively protect large flake graphite. After comparing four different shapes of media: ball, rod, column and cylinder rod, it was found that the cylinder rod medium plays a significant role in protecting large scales during the grinding of graphite ore. Its contact with the mineral is mainly surface-based.

Flake graphite has a non-polar mineral surface, and neutral oil collectors are used to facilitate flotation. However, graphite itself has the characteristics of lubricity and is difficult to separate from gangue minerals during grinding. Especially for the separation of fine-grained minerals, when using ordinary flotation machines, the process flow is relatively long and the separation efficiency is low. Therefore, when choosing a flotation process, you should choose a process that protects large scales, yields more and earlier, and is simple.

A one-stage coarse grinding is adopted, and the coarse concentrate is then reground and multi-stage beneficiated. This process can obtain higher-grade concentrate and effectively reduce the loss rate of large pieces of graphite. However, the process flow is too long and the production cost is high. The flake graphite regrinding process is improved, and a two-stage vibration mill is used instead of the traditional four-stage ball mill. This can not only simplify the process, but also reduce the graphite flake loss rate, stabilize the production index, and also significantly improve the grade of final graphite concentrate.

Under the condition that the total regrinding time remains unchanged, although increasing the number of regrinding stages has little effect on improving the final concentrate grade, it can significantly increase the yield of large graphite in the final concentrate, indicating that multi-stage regrinding has a great impact on protecting graphite. The scales have a significant effect. The main reason why multi-stage regrinding can increase the yield of large flakes is to reduce the damaging impact of gangue minerals on graphite flakes during the grinding process. The main gangue minerals in flake graphite ore are quartz and pyroxene. Their hardness is much greater than that of graphite flakes. During the grinding process, they have a strong grinding and peeling effect on the graphite flakes, causing the dissociated graphite flakes to be ground. Thereby reducing the yield of large pieces of graphite, while using multi-stage regrinding will increase the yield of large fragments of graphite due to the reduction in gangue mineral content during subsequent regrinding, which reduces the grinding and peeling effect of gangue mineral particles on graphite flakes.

Large flake graphite has many special properties, so it has high economic value and is highly competitive in the international market. During the sorting process, graphite flakes are extremely susceptible to damage due to their low hardness. There are two main factors that affect the yield of large flake graphite: first, the complex regrinding process during the grinding process leads to unnecessary overgrinding; second, the harder gangue during the grinding process destroys the graphite flakes. Therefore, the dissociated large scales should be recovered as early as possible during the sorting process.

The specific gravity of quartz-based gangue is not much different from that of pure graphite flakes, but the ratio is small. It is an extremely difficult mineral to select and cannot be separated based on the specific gravity difference alone. In production practice, shaking table gravity separation not only plays a role in specific gravity difference, but also plays an enrichment role in minerals of different shapes. The specific gravity of graphite flakes and gangue minerals are close. During gravity separation, the water-facing area of graphite flakes is large, and the resistance increases, which reduces the sinking speed. Therefore, graphite is located on the upper layer of the bed surface. The facing surface of the gangue minerals is small, the resistance is reduced, and the sinking speed is accelerated, so the gangue minerals are located at the bottom of the bed surface. Therefore, the force of water flow on graphite flakes and gangue minerals is opposite, which can produce obvious zoning, achieving the purpose of sorting.

The above are some factors that affect the flake graphite mineral processing. In production practice, avoiding factors that may cause damage to large graphite flakes and affect the separation efficiency can improve the recovery rate of concentrate and large graphite flakes, thereby improving resource utilization and economic benefits of plant selection. Choosing a suitable graphite beneficiation method has an important impact on the effective recovery of concentrates. Xinhai Mining recommends selecting customized graphite beneficiation plans and equipment according to the characteristics of the ore, so as to improve the efficiency of mineral processing. If necessary, please feel free to consult Xinhai Mining.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.