Metal lead and zinc occupy an important position in industrial production. With the continuous development of industry, easy-to-select lead-zinc sulfide ores have been unable to meet industrial demand. Therefore, it is necessary to develop difficult-to-select or low-grade lead-zinc sulfide ores, and at the same time improve existing utilization efficiency of sulfidized lead-zinc ore. Various minerals in lead-zinc ores are closely associated, and the effects of various ions on target minerals are also complex and changeable. These reasons will seriously affect the processing and utilization of lead-zinc ores. The following will introduce to you the reasons why sulfidized lead-zinc ore is difficult to separation and the relationship between various ores.

The lead ore in common lead-zinc sulfide ore is galena, and the zinc ore is sphalerite. Since there are relatively few single lead sulfide ores and zinc sulfide ores in nature, they are mainly lead-zinc sulfide polymetallic ores. However, sphalerite and galena are more complex in many aspects such as surface properties, crystal structure, association relationships, and embedded state, which makes it difficult to separate lead-zinc sulfide ores.

Galena and sphalerite in lead-zinc sulfide ore are associated with pyrite and are difficult to separate through flotation. Sometimes some of the lead minerals in lead-zinc sulfide ores are wrapped in sphalerite in the form of particulates. For such types of lead-zinc ore, simple crushing and grinding cannot achieve the monomer dissociation of various minerals, and thus It will cause the quality and recovery rate of lead concentrate and zinc concentrate to decrease.

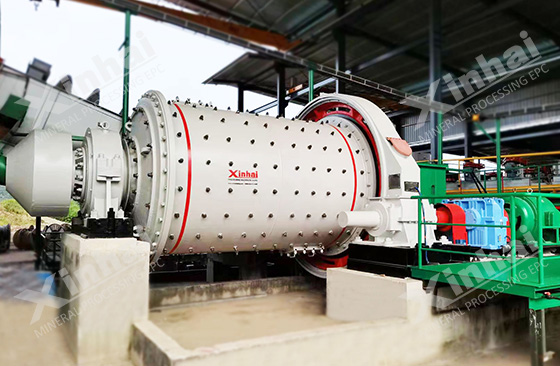

Sometimes the intercalation relationship in lead-zinc sulfide ore is relatively complex, and the intercalation or dissipation particle size is uneven or extremely uneven. However, galena and sphalerite in the ore are the main sources of lead-zinc ore concentrate. The maximum particle size can be 1-20mm and the minimum can be 0.004-0.01mm. It should be noted that the finer particle size of the ore will aggravate the The degree of oxidation of minerals. When the grinding fineness does not meet the requirements, sphalerite and galena easily enter each other's concentrate products, resulting in a decrease in concentrate quality and recovery rate. However, it is also necessary to control the grinding fineness of lead-zinc ore. If it is too fine, the lead concentrate will be lost. The optimal grinding fineness selected by different concentrators is different. When the ore is ground to the optimal particle size, the beneficiation effect is ideal. At the same time, it can also ensure the selective flotation of galena and sphalerite and improve the concentrate recovery rate and grade.

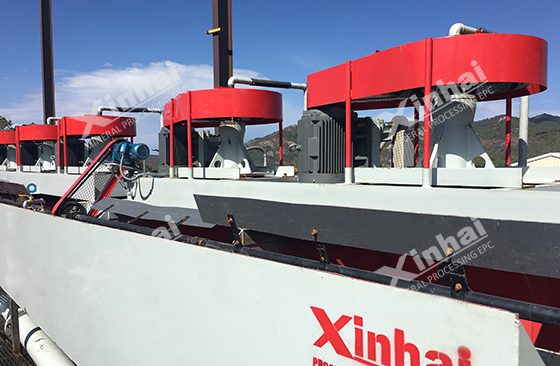

The floatability of galena is better than that of sphalerite, but it is difficult to activate galena once suppressed, and in polymetallic sulfide ores such as lead-zinc ore, copper-lead-zinc ore, and zinc-sulfide ore, the lead content Usually lower than zinc. Therefore, when dealing with lead-zinc sulfide ore, one usually chooses to first suppress zinc ore and flotate lead ore. According to the difference in floatability of minerals, the concentrator will choose to use a preferential flotation process to suppress the zinc-sulfide ore and float out the lead concentrate, and then suppress the flotation of the iron sulfide ore to separate the zinc concentrate.

The zinc content in lead-zinc ores is high, and a large amount of inhibitors need to be added to inhibit zinc sulfide during flotation separation, which increases the cost of the reagents. However, it should be noted that insufficient selection of reagents may lead to lead concentrate The zinc content yields a normal level, which in turn affects the quality of the lead concentrate and the recovery rate of zinc. When the traditional high-alkali process is used to treat lead-zinc sulfide ore, sphalerite is easily inhibited and affects the recovery rate of zinc. Reducing the amount of lime will also lead to excessive zinc impurities in the lead concentrate. Since lead-zinc ores are associated with useful mineral components such as gold, silver, and copper, the recovery of these minerals should be taken into consideration when recycling lead-zinc ores. Therefore, the mineral processing process of lead-zinc sulfide ores will be further complicated, which is also the difficulty of separating lead-zinc ore by flotation.

From the above content, we can understand the complex relationship between different minerals and their impact on the sorting process in optimizing the sorting process of sulfidized lead-zinc ore. Therefore, when determining the mineral separation process, one should fully understand the mineral characteristics. Developing a separation process based on the mineral characteristics can improve the separation efficiency of the ore. With the continuous development of technology, the continuous application of advanced separation technology to process lead-zinc sulfide ore can achieve maximum utilization of lead zinc ore and improve mineral processing efficiency and production efficiency.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.