As time progresses, a new chapter unfolds. Reflecting on our journey, XinHai has achieved remarkable success in the mining industry, driven by innovation and guided by responsibility. As we stand at the threshold of a new year, let us look back on the milestones of 2024, celebrating the breakthroughs and accomplishments of each project, and drawing greater momentum and determination for the year ahead.

Xinhai Mining is making steady progress in the 1.2 million tpa copper ore dressing plant project in the Middle East. The design of the ore dressing plant in this project follows advanced and reliable process technology, and uses large-scale and efficient equipment and advanced control technology, aiming to create an efficient and economical production system with optimized input. According to the contract with the customer, Xinhai is responsible for completing the construction drawing design, including the general plan, ore dressing process, electricity, water supply and drainage, tailings and other professional designs, and formulates efficient and reliable process flow through ore selectivity tests.

Xinhai Mining completed a 10,000tpd heavy sand ore wet separation production line construction project in Mozambique, covering the raw material system, pulping system, roughing system, scrubbing system, magnetic separation system and selection system. In view of the ore characteristics of local laterite-type and coastal-type zirconium-titanium placers, Xinhai has innovatively optimized the mineral processing process, using "one rough, one fine, one scavenging" and "screw scavenging, sweeping + shaking table selection" etc. technology to ensure efficient separation of zircon titanium ore and silica sand, ilmenite and zircon sand. At the same time, through the "five minus one plus" optimized design, the rationality and economy of the process are greatly improved, the height difference is fully utilized to realize the self-flow of slurry, the equipment configuration is simplified, and the construction and operating costs are reduced. The entire design process strictly follows national standards to complete the multi-professional construction drawing design of mineral processing technology, equipment, electricity, civil engineering, etc. The equipment configuration fully reflects the concept of "maturity, reliability, safety, and environmental protection", and finally achieves the entire line to meet standards and production, bringing customers Significant benefits.

Xinhai Mining successfully completed the flotation expansion project of the 1500TPD silver-lead-zinc-gold polymetallic mine in Henan Province, China. It provides a full range of services for the technical transformation and expansion of the mine. The project includes the construction and renovation of multiple core facilities such as the intelligent waste disposal system, powder ore bin, grinding workshop and flotation workshop, 18m thickener, concentrate filtration workshop renovation, high and low voltage substations and 2000m³ high-level water tank. During the construction process, facing the complex construction conditions such as small site, demolition and construction, and frequent rainfall during the flood season, Xinhai relied on its professional first-level qualification for general contracting of mining engineering and rich project management experience, and was not afraid of challenges, ensuring the project was delivered on time with high quality.

Xinhai successfully promoted the Indonesia 200tph limestone preparation project, providing efficient preparation solutions for customers' mining production. The design of this project covers many professional fields such as general layout planning, mineral processing process design, civil engineering structure, water supply and drainage, ventilation, electricity and automation. According to the needs of the owner, Xinhai designed the process flow as "ore crushing-grinding and classification" to achieve a processing capacity of 200 tons of ore per hour. Within the tight construction period, the Xinhai team ensured the high-standard completion of the project with professional design capabilities and efficient execution.

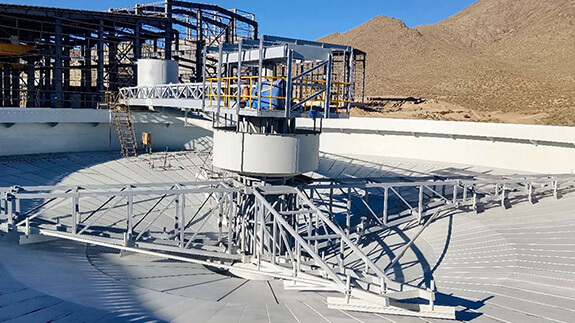

Xinhai Mining successfully promoted the construction of Xinjiang 50,000 tpd low-grade ilmenite beneficiation plant project. The project mine area is rich in resources. After multiple surveys and detailed investigations, the preliminary exploration of iron ore resources has reached 251.1065 million tons and TiO2 metal content has reached 14.0659 million tons, providing sufficient guarantee for future mine development.

Xinhai adopts the innovative "crushing + high-pressure roller mill + ball mill" crushing and grinding process in the design, which greatly reduces energy consumption, and reduces the amount of ore entering the mill through the ultra-fine powder ore dry separation process, which reduces the burden of the mill and effectively reduces the pressure of the tailings pond. In addition, in terms of titanium ore separation, Xinhai adopts the "strong magnetic + flotation" process combined with the high-concentration flotation titanium process, with a flotation concentration of up to 50-60%, which improves the titanium selection effect and has stable and reliable technology. The vertical mill is used for the re-grinding of titanium coarse concentrate, which not only improves the grinding efficiency, but also improves the working environment and reduces noise and vibration. The smooth progress of the project has also created local employment opportunities and promoted economic development.

Xinhai successfully completed the Middle East 1200tpd gold mine expansion project, which includes the expansion and installation and commissioning of the first phase 500tpd and second phase 500tpd beneficiation plants, covering the powder silo, grinding workshop, leaching workshop, concentration (water pool) workshop, tailings dewatering workshop and desorption electrolysis workshop and other process links, involving water supply and drainage, electricity, civil engineering and general layout and other multi-professional collaborative design. The beneficiation process designed by Xinhai is raw ore crushing-grinding classification-cyanide leaching-gold-containing precious liquid adsorption-desorption electrolytic smelting-tailings dehydration, ensuring a high gold recovery rate and meeting the strict requirements of customers. During the implementation of the project, Xinhai optimized the pipeline design to ensure continuous production during the transformation, without dismantling existing facilities or stopping production, and without affecting customer revenue. The first phase of construction took only 1 year and 9 months, and the second phase took only 10 months to achieve full production. After commissioning, the processing capacity reached 1,300tpd, and the output and recovery rate exceeded customer expectations. With the advantages of fast construction speed, active response to problems, and stable process operation, Xinhai has won the high trust and recognition of customers.

Xinhai Mining successfully delivered and promoted the Shandong 100,000 tpa Ultrapure Iron Concentrate Project. The project relies on the original plant to implement the old plant area renovation to maximize the efficiency of resource utilization. Based on the research results of the selectivity test of Xinhai Mining Research Institute, an efficient "two-stage two-closed-circuit grinding, magnetic separation + two-stage reverse flotation" process was designed and implemented to produce ultrapure iron powder with a grade of 71.76% and a recovery rate of 65.36%, as well as high-purity iron powder with a grade of 70.63% and a recovery rate of 30.50%. Xinhai not only completes the full process service from mineral processing test to construction drawing design, equipment manufacturing, installation and commissioning, and worker training, but also provides a one-stop solution for installation materials, electronic control equipment and related tools. During the implementation of the project, Xinhai Mining's innovative technology was combined with refined management to ensure the smooth realization of the construction goals, which was highly recognized by the owner and thanked in a letter.

Xinhai Mining successfully completed the general contracting project of a 600tpd gold ore dressing plant in Hebei, China. The project was based on a comprehensive optional test study, a detailed analysis of the mineralogy and distribution characteristics of the ore, and a scientific flotation process plan was formulated. Experimental research shows that the gold grade of the raw ore of this gold mine is 3.29g/t, and the silver grade is 6.20g/t. The main gold-bearing minerals are pyrite, chalcopyrite and limonite. The mineral embedding characteristics are suitable for flotation. Craftsmanship. The closed-circuit flotation process recommended by Xinhai is a flotation process of one coarse, two sweeps and two fines or one coarse, two sweeps and one fine, and the Au grade is 64.78g/t, the recovery rate is 94.94%, and the Au grade is 44.58g/t, and the recovery rate is obtained respectively. The flotation concentrate with a rate of 95.64% has a silver recovery rate of over 60%. This process solution not only meets the different taste needs of customers, but also significantly improves resource utilization efficiency and economic benefits. The successful completion of this project provides a strong guarantee for the customer's subsequent production.

Xinhai Mining successfully completed the 400TPD gold mine general contracting project in Latin America. The project demonstrated a high level of execution and professional capabilities in design, equipment, installation and commissioning, and automation engineering. According to the high standard requirements of customers, Xinhai equipped the project with international brand equipment such as Siemens motors, SEW reducers, and ABB electrical components, and provided a full set of automated process detection instruments and central control systems. At the same time, the safety and reliability of the equipment are ensured through the all-bolt steel structure design. After the project was successfully completed, the dressing plant carried out a test run with materials, and all indicators performed well. The ore grade was 3-5 g/ton, the recovery rate reached 92%, and the processing capacity was stable at 500 tons per day. At present, the processing plant is operating smoothly and achieving continuous withdrawals, bringing significant economic benefits to customers.

Xinhai Mining successfully promoted the 500,000 TPA wollastonite mining general contract operation project in Jiangxi Province, China. The Xinhai team entered the site in advance according to the owner's needs, completed 16 hidden danger rectification tasks, and successfully passed the acceptance inspection, laying a solid foundation for the mine to be officially put into operation. During the operation management process, Xinhai provides a full range of services including mine operation management, production scheduling and control, technical support and improvement, equipment maintenance and management, safety management and environmental management. Combined with the mine's geological characteristics and mineral processing production needs, we scientifically formulate mining plans to ensure the balance of three-level ore and ensure stable ore supply. At the same time, we strictly control the mining dilution rate, loss rate and operating costs to help the mine achieve efficient, safe and civilized production. With its first-level mining engineering general contracting qualification and the support of a professional team, Xinhai provides customers with high-quality operation and management services, which not only reduces the operating costs of the mine, but also significantly improves production efficiency, winning high recognition from customers.

In 2024, Xinhai Mining forged ahead with resilience, overcoming challenges and steadily advancing every mining project, achieving outstanding milestones along the way. Looking to 2025, Xinhai Mining is set to embark on a new journey, striving to push boundaries, tackle challenges, and deliver more efficient and innovative full-spectrum mining services. Each project will shine brightly, embodying the spirit of dedication and progress as the company continues its pursuit of excellence and reaches for new heights.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.