Gravity separation method is the earliest method that applied in mineral processing. According to the density difference among mines and the difference of gravity, fluid power and mechanical force in moving medium, mines realizes mineral grains separation by density difference, gravity separation still occupies an important position in the contemporary mineral processing methods.

Since founded in 1997, Xinhai Mining has constantly increased scientific research and technology of gravity separation method. During more than 20 years of exploration, Xinhai constantly improved gravity separation method, aims at providing customers with more environmental and efficient gravity concentration and gravity separator.

Gravity separation method is widely applied in gold ore, tungsten ore, tin ore, manganese ore, mercury ore, titanium ore, lead ore, tantalum-niobium ores, galena, barite, fluorite ore, pyrite, limonite, hematite, antimony, chromium ore and ferrous metal.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Xinhai gravity separation method simplifies the production process and avoids over-cycles; Tailings has less environmental pollution; Xinhai gravity separator has a simple manufacture, better stability, which saves energy and reduces cost.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

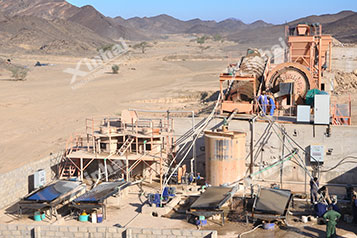

Ore property: The plant was located in erosion hills, and paragenetic mineral of gold placer are mainly magnetite, ilmenite, followed by limonite and rutile.

Project problem: Gold placer existed in native gold, the particle sizes was coarse from 0.1~1.0 mm, those that were less than 0.074 mm has little gold, and no colloidal clay, and it was washing gold placer. But the water shortage was the big challenge for this project.

Xinhai solutions: Xinhai decided to adopted two-stage jig, shaking table concentration process, which directly produced gross gold and heavy concentrate. Combined with the project of water shortage and terrain topography, Xinhai adopted mechanical mining and mechanical delivery, focused on building machine-processed plant, and gravity separation method has simple equipment and relatively perfect process, which not only saved cost, but also improved recovery rate of gold placer.

Process indicator: Gold placer grade: 0.811g/m3; Gross gold grade: 85%; Recovery rate of gross gold 93.38%

Ore property: The tungsten ore was feldspar-quartz vein type deposit. The main metallic minerals were wolframite, followed by scheelite, The metallic minerals accounted for 3-5% of total amount of ore.

Project problem: Wolframite was associated with quartz from 10~15mm to 0.01 mm; Scheelite was associated with pyrrhotite and other sulfide minerals, the particle size was about 0.2 ~ 0.01 mm. The raw ore contained 4% silt content and 6-7% water content.

Xinhai solutions: After the mineral processing experiments, Xinhai decided to adopt three stage jig, four stage shaking table, mud and sand separation based on ore properties. Coarse, medium grain jig tailings were sent to rod mill, and the ground was returned to double vibrating screen, which formed a closed cycle. The shaking table is used in twice separation, coarse grain was returned to the closed cycle, the fine grain was returned the original work. Slime individual treatment, including coarse level table recovery, fine to original process. The pulp need to be handled separately, and shaking table recycling was adopted in the coarse grain, centrifugal separator recycling was adopted in the fine grain, ultimately the whole process obtained jigging rough concentrate, shaking table rough concentrate and fine mud rough concentrate.

Process indicator: Concentrate grade: 66.11%; Tailings grade: 0.038%; Recovery rate: 83.67%

Ore property: The ore is cassiterite polymetallic sulfide ore. The main metals were tin ore, pyrite, and marmatite.

Project problem: The metal minerals disseminated unevenly, most of them were immersed in vein or surrounding rock, and the aggregate grain is coarser. The tin ore was distribution as stripped, and alternated with various sulphides, especially associated with pyrite, and embedded with gangue.

Xinhai solutions: Xinhai decided to adopted heavy medium primary, gravity separation-flotation-gravity separation process .Based on the fine grain of tin ore pulp and slow fall velocity, Xinhai adopted centrifugal concentrator for roughing and discarded a large number of tailings. In addition, Xinhai used 6s shaking table to process centrifugal concentrator coarse ore and Xinhai spiral chute tailings, which simplified the production process, prevented the vicious cycle of middling, and maximized tin ore recovery. Compared with single tin concentrate separation process, Xinhai gravity concentration increased 5~10% recovery rate, and the recovery rate of primary ore was improved by 1.5~2.0%.

Process indicator: Ore grade: 0.68%; Concentrate grade: 69.62%; Recovery rate: 85.25%

If you have any questions, please contact us by the following ways, and we will provide you with better help!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.