Installation and commission is key link of realizing dressing test, mine designand equipment manufacture, and directly takes influence on production.

Installation and commission includes: equipment packing, shipping, site installation and commissioning.

Installation and commission of dressing plant equipment is a very careful work with strong practicality. Any error may lead to low recovery which cannot reach the expectation. For example: in different construction, the same type of equipment would have deviation because of the opening location, installation, water and reagent usage, etc. These differences will have a significant impact on the final recovery rate.

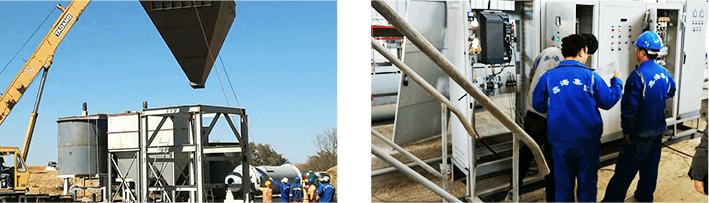

In view of the importance of installation and commission, Xinhai established professional installation company having four installation teams which are from the mine production line and led by engineering technicians who held the directors of dressing plant and mine leader. Installation personals Xinhai sent out participate in the whole mine design of clients, and there are two points for this: one is the old technicians are very familiar with structure, performance and using of Xinhai equipment; the other is the technician who can quickly solve many actual problems in plant construction understand the overall design of factory because of participating in the whole mine design.

For installation and commission, Xinhai upholds customer fist. There are 3 methods of installation and commission according to the actual situation of customers.

Xinhai can send related veteran technician to guide customer with the equipment installation and commissioning for saving customer's cost.The customer should responsible for the travel charge of the technician.

Xinhai arranges the installation and commission technicians, and clients prepare the components and instruments of installation of commission.

Xinhai is responsible for tools, materials and personnel allocation of the installation and commission. Customers can directly wait for the final results.

Since founded, Xinhai Mining always holds the idea of customer-oriented. Split joint living quarters is proposed by Xinhai Mining based on convenient customer service. Many mineral processing plants and mines of Xinhai customers are located in remote mountain area, the daily life of factory personnel becomes a big problem, split joint living quarters is easy to remove and storage, which can be used repeatedly, so it is the best choice for mineral processing plants in remote areas.

The right is split joint living quarters designed by Xinhai, the total staff number is 90 people, management and service personnel are 20 people, and workers are 70 people. Factory is equipped with office, dormitory, and dining room, laboratory, conference room, activity room, and restroom, wash bath.

Gold smelting is the last process in the gold production, and the final product is the finished gold.

Xinhai has a professional gold smelting technical team, proficient in aqua regia method, electric chloride control method, electrolysis method, extraction method and other fire and wet gold refining and refining processes. In the course of years of design services, Xinhai has accumulated rich design experience and reached the world's advanced level. Moreover, Xinhai could provide targeted technical design services according to the material nature, production scale and product quality requirements provided by customers.

Xinhai has proprietary gold refining technology, which has the following characteristics:Short process, strong material adaptability, advanced technical indicators, high product quality standards, meet the requirements of Shanghai gold exchange and national standards;Zero backlogs of process materials, low production cost, stable index, simple operation, fast production, thus accelerating enterprise capital turnover; Wastes comprehensive recovery, recycling, exhaust emission standards, and excellent working environment.

Please leave your message here! We will send detail technical info and quotation to you!

© 2020 Shandong Xinhai Mining Technology & Equipment Inc.