Xinhai High Quality Steel Ball to Improve Your Grinding Efficiency and Reduce Grinding Cost

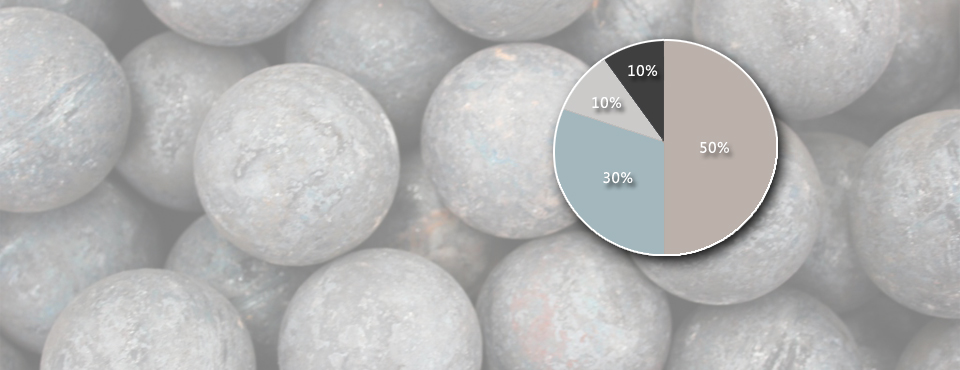

Grinding Equipment

Grinding Equipment Energy Consumption

Energy Consumption Grinding Medium

Grinding Medium Personnel and Others

Personnel and Others

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.