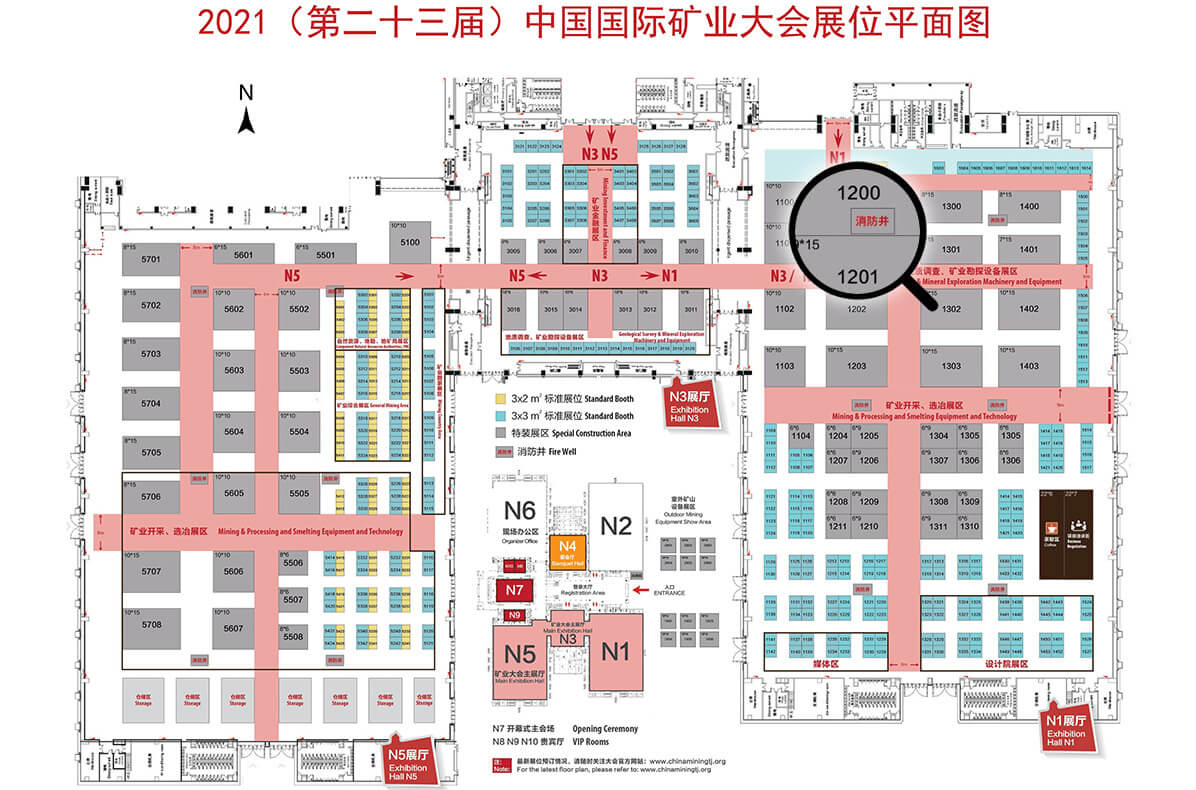

China Mining Conference and Exhibition 2021 consists of three parts – conferences, exhibition and promotion meetings. Aiming at the hot issues facing the global mining industry under the new situation, it provides a platform of communication and cooperation for professional organizations, buyers and participants, such as mining right holder, investors, technology service provider, equipment manufacturers.

Tianjin Meijiang Convention and Exhibition Centre

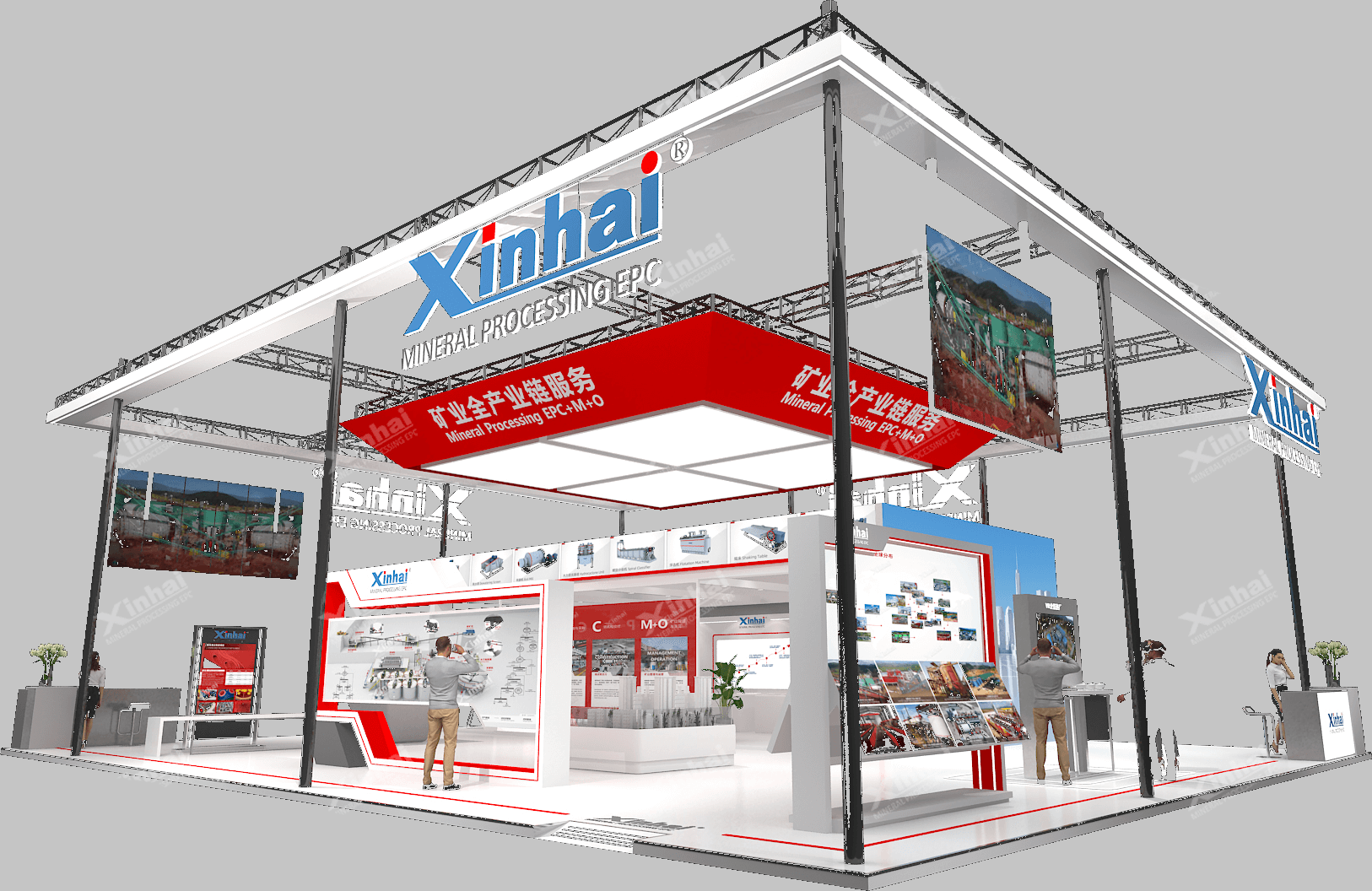

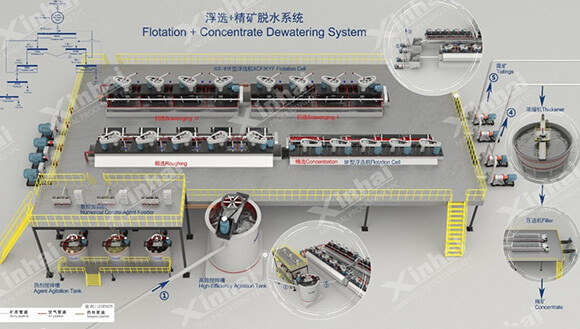

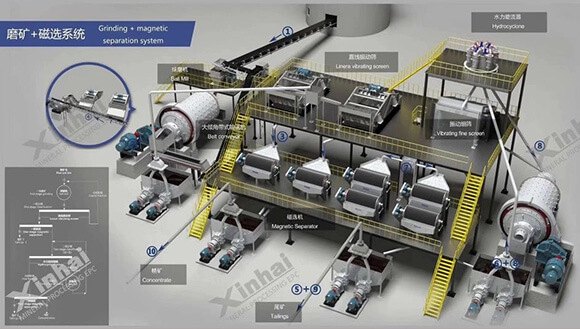

Xinhai devotes to providing “Turn-key Solution for Mineral Processing Plant”, namely “design and research- complete equipment manufacturing and procurement-commissioning and delivery - management and operation”.

The essence of “EPC+M+O Service” is to provide more detailed service for every link. Xinhai defines “EPC+M+O Service” as the major and featured product, which fits for most mines.

Up to now, Xinhai has conducted design and research and supplied equipment for about 2000 mines, completed 500 mine EPC+M+O projects, accumulated rich mining technologies and experience of 70 kinds of ores, and applied for many patents. Xinhai has established overseas offices in many countries with products exported to more than 90 countries.

E

E

Customize the mineral processing solution with innovative and open type thought;

Non-standard parts and pipelines are professionally designed by mechanical and pipeline professionals respectively, then reviewed by the installation team before make plans and delivery;

Fully consider the site limitations on the later installation and commissioning, such as the steel structure and combined steel structure are adopted in the foreign mines with high civil construction costs.

P

P

High-standard equipment manufacturing capacity and accessory matching capacity;

Provide the equipment with unified standards and adapted to foreign site conditions;

All documents are organized and translated in a unified format (including 3D part drawings, etc.);

Organize the packaging plan, implementation, delivery and customs clearance according to the overall production line, installation materials, spare parts, etc.

C

C

Simulate the material planning, packaging and delivery for site installation, avoiding the prolonged construction period and increased investment cost due to material loss or inventory overstocking after people and goods arrive the site;

Careful and executable construction technical scheme, strict assessment scheme, avoiding the cost increase due to repeated changes in the technical scheme;

Experienced construction, installation and commissioning team

M+O

M+O

Management service in construction period and operation service in production period

Collect, monitor and analyze all production online data,

the

data utilization rate is 100%

Automatic crushing/grinding/pumping station, centralized control+ intelligent inspection

The concentrator personnel are reduced by 20%

Guarantee the premise of production index,

2%-4% of the

processing capacity when raising the grinding table

The management efficiency is improved by 20%

through

intelligent analysis and sorting of production

and operation data, information

push.

A large-scale iron mine in South America contains a certain amount of copper. One large-scale enterprise adopted a traditional process — crushing on site, dry separation for discarding non-magnetic ores. A large number of non-magnetic copper are discharged, the rest of copper is treated by flotation as the borderline sulfide.

There were recyclable non-magnetic copper minerals in iron ores, therefore, traditional process of dry separation for discarding non-magnetic ores was not adopted.

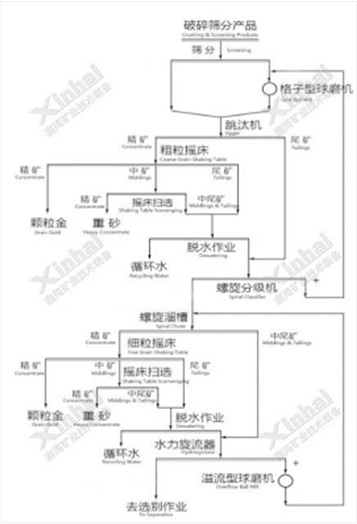

Due to the fragility of copper minerals, one stage of grinding and two stages of classifying were adopted. Enlarging the discharging particle size of ball mill and adding one stage of flash flotation in grinding and classifying circuit were to ease the argillization; adding one stage of flash flotation before roughing in flotation process was to separate the copper minerals with fragile foams as fast.

One stage of scavenging was added after concentration I to prevent concentration tailings from flowing into the iron products, so as to obtain sulfur concentrates. This process was rarely used before.

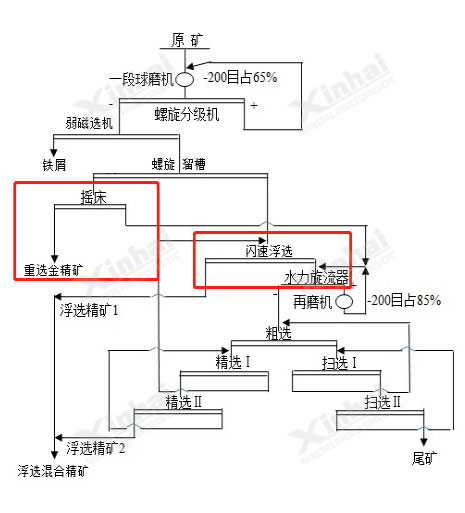

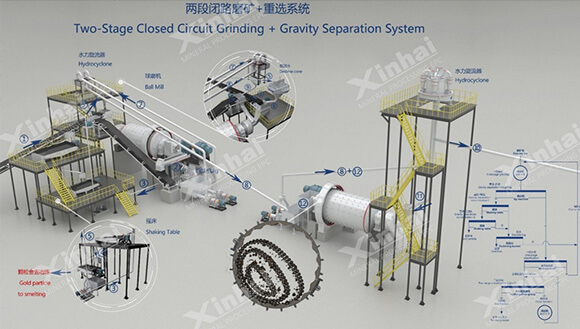

The mine was the surface mixed gold mine, and the all-slime cyanidation process is prohibited by the local government. Originally, four well-known domestic research institutions adopted flotation process, and the best recovery index was 82%. But Xinhai adopted gravity separation to obtain gold concentrate and flash flotation process, the recovery rate reached 90%.

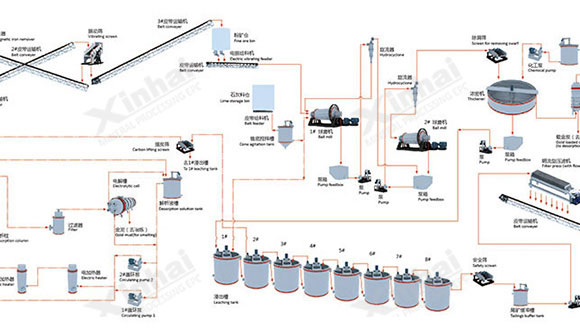

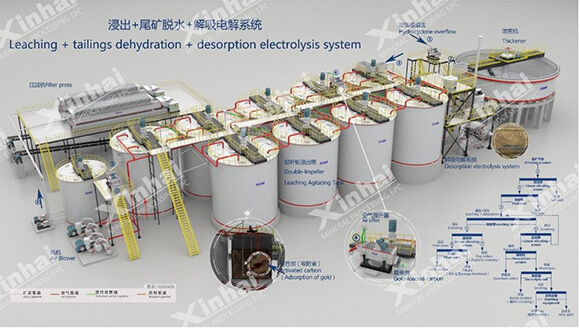

Gold all-slime cyanidation CIP plant

Gold all-slime cyanidation CIP plant

Gold all-slime cyanidation CIP plant

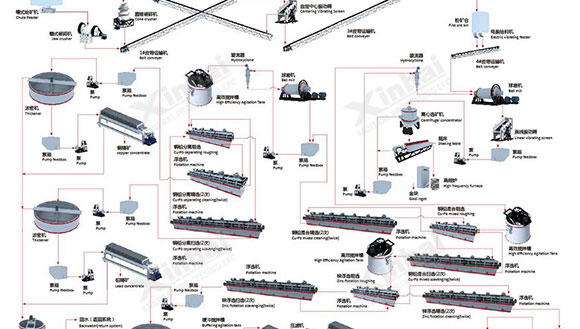

Peru copper, lead and zinc mineral processing plant

Peru copper, lead and zinc mineral processing plant

Peru copper, lead and zinc mineral processing plant

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.